An ATC, or an Automatic Tool Changer, is among the most advanced technological devices, inbuilt into CNC machines for versatility and commute efficiency. Because, by automating the tool changing process during machining operations, ATCs avoid the need for intervention by humans, thus accelerating manufacturing. This technology is an asset in use today for woodworking, metalworking, electronics, and other industries where frequent tool switching is important.

How Does an Automatic Tool Changer Work?

An ATC is a unit which enables the storage and retrieval of various tools using the machine tool for a machining operation. Here is the process of the ATC.

- Tool Selection: The CNC controller instructs the ATC to select the tool on the basis of machining requirements.

- Tool Release: The tool in the spindle is released and it goes back to its location in the tool magazine or carousel.

- Tool Pickup: The new tool is picked up from the ATC and within the spindle it is firmly clamped.

- Operation Resumes: The machine resumes again, with little delay.

This is the most effective system through which multi-step machining processes can be accomplished.

Types of Automatic Tool Changers

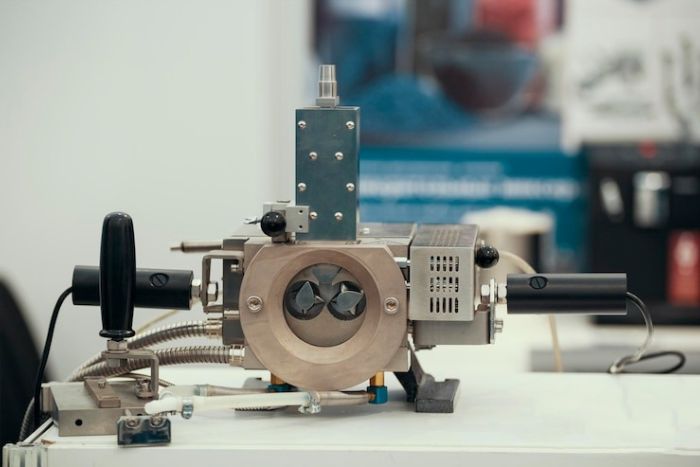

- Carousel Type: This A-T-C consists of a circular magazine that stores tools. It’s compact and most widely used as an Automatic tool changer for CNC routers.

- Chain Type: This has a linear or looped chain as storage for tools. This is best for large-scale operations requiring numerous tools.

Both types are designed to fulfill specific operational needs for maximum compatibility with various CNC machines.

Benefits of Using an Automatic Tool Changer

- Productivity Enhancement: Automatic tool changers implement a lot of time for manual tool changes, leading to continuous working without stopping operations. This is much needed in high producer settings.

- Enhanced Accuracy: The tool-changing process is complete and does not involve the hands of any human; therefore, it becomes error-proof to ensure precise work during all machining.

- Lower labor costs: The routine functions make companies less dependent on costlier manual work.

- More Versatile Machines: CNC machines equipped with ATCs can perform several jobs in one setup switching seamlessly between drills, cutters, and engravers.

- Shortened production cycles: With minimal time spent changing tools, production cycles are shortened and more output is generated.

Applications of Automatic Tool Changers

- Woodworking: CNC routers are used for furniture production, allowing drilling, carving, and engraving in one operation. Metalworking Performs milling, drilling, and cutting with precision.

- Electronic manufacturing: Imports CDU cutting and engraving processes.

- Automotive industry: Allows the manufacture of parts that have subtle shapes and require various tools.

Why Is an ATC Important for CNC Routers?

In terms of CNC routes, automatic tool changers for CNC routers play an important role in productivity. With them, the machine can be fed with pieces containing complex designs requiring multiple tools, and subsequently execute those designs without human intervention. Therefore, the CNC router becomes even more versatile in tackling precision tasks with applications in most industrial settings that handle multiple machining jobs.

Conclusion

An Automatic Tool Changer is really invaluable for today’s CNC machining, enabling incredible speeds with fantastic precision and increased efficiency. Whether for CNC routers or milling machines, adding an ATC system is most strategic for companies optimizing their manufacturing processes. ATC systems ensure consistent quality, downtime reductions, and overall productivity gains as they perform tool changes automatically. It has now finally become a necessity for industries wishing to remain competitive.