CNC machines have revolutionized the manufacturing industry with automation, precision, and efficiency. Whether you’re a production manager, machinist, or a buyer looking for CNC machine manufacturers in Melbourne, understanding the types of CNC machines is crucial.

Let’s explore the top 5 CNC machines that dominate the modern workshop floor.

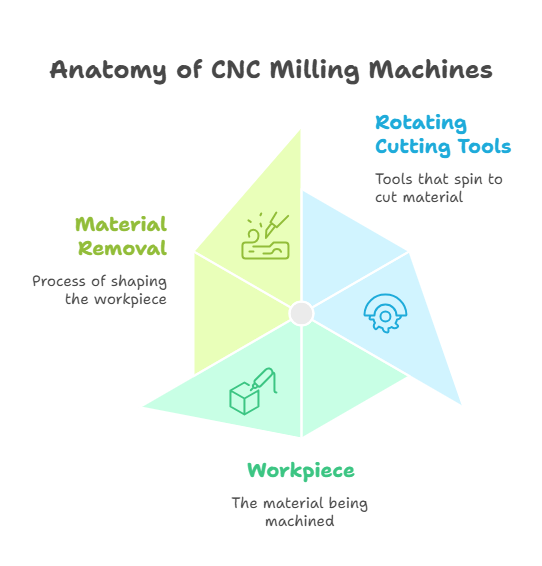

1. CNC Milling Machines

CNC milling machines use rotating cutting tools to remove material from a workpiece.

Key Features:

- Ideal for complex parts & precision components

- Supports 3, 4, or 5-axis machining

- Common in automotive, aerospace, and toolmaking

Popular Use Cases:

- Engine components

- Mold tooling

- Metal prototypes

2. CNC Lathes (Turning Machines)

CNC lathes rotate the workpiece while a cutting tool shapes it.

Key Features:

- Great for cylindrical and symmetrical parts

- Excellent for high-speed production runs

- Ensures consistent, repeatable precision

Common Applications:

- Shafts

- Bushings

- Threads

3. CNC Plasma Cutting Machines

CNC plasma machines use a plasma torch to cut through conductive metals.

Key Features:

- Best for steel, aluminum, copper

- Fast and cost-effective

- Ideal for sheet metal fabrication

Industries Served:

- HVAC

- Automotive body shops

- Structural fabrication

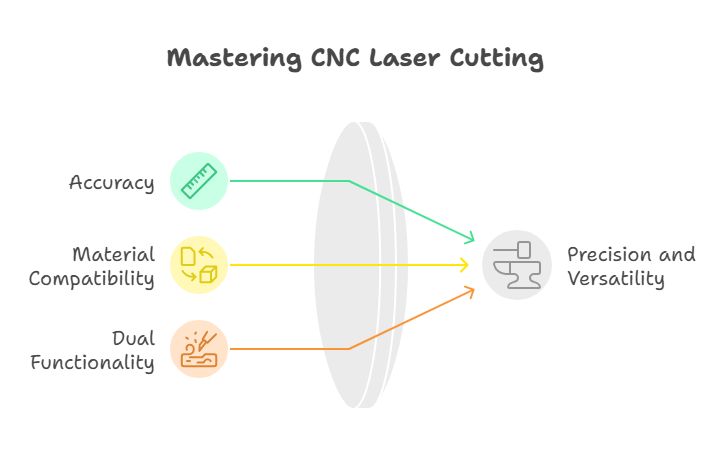

4. CNC Laser Cutting Machines

These machines use high-powered lasers for intricate, precision cutting.

Key Features:

- Highly accurate and clean cuts

- Perfect for delicate materials like acrylic, wood, or stainless steel

- Supports both engraving and cutting

Use Cases Include:

- Custom signage

- Electronics casing

- Decorative metalwork

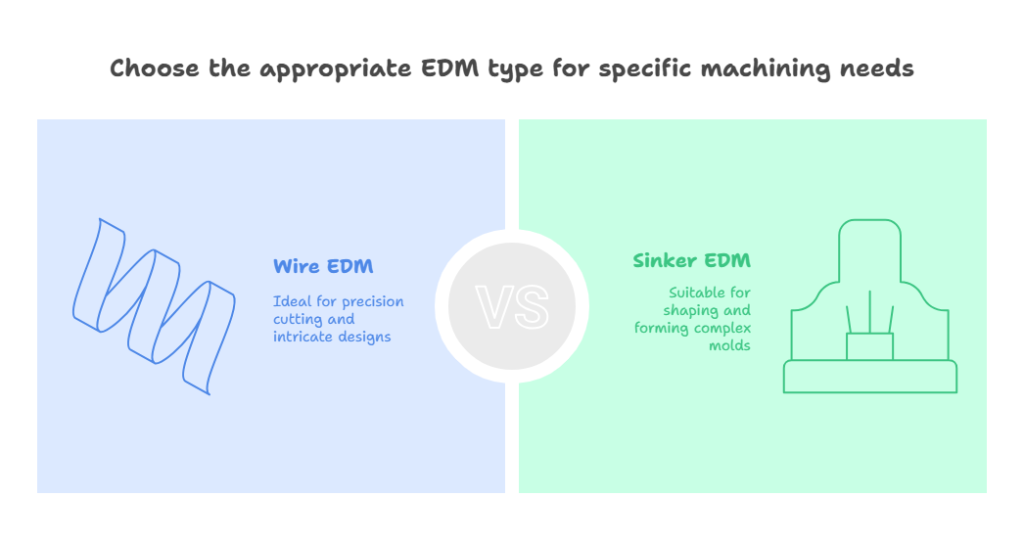

5. CNC Electric Discharge Machines (EDM)

EDM machines use electrical sparks to remove metal from workpieces.

Key Features:

- Suitable for hard metals or complex geometries

- Commonly used in die and mold industries

- Includes wire EDM and sinker EDM

Applications:

- Injection mold tooling

- Aerospace components

- Intricate part shaping

Comparison Table: Types of CNC Machines

| CNC Machine Type | Ideal For | Industries | Precision Level |

|---|---|---|---|

| Milling Machine | Complex parts | Aerospace, Auto | Very High |

| Lathe Machine | Cylindrical parts | Manufacturing | High |

| Plasma Cutter | Sheet metal | Fabrication | Medium |

| Laser Cutter | Thin, delicate parts | Signage, Crafts | Very High |

| EDM Machine | Complex/hard metals | Tooling, Molds | Extremely High |

Why Choose Reputed CNC Machine Manufacturers?

Investing in the right CNC machine manufacturer ensures:

- Long-term ROI

- Durability & warranty support

- Technical training & after-sales service

If you’re searching for trusted CNC machine manufacturers in Melbourne, ensure they offer:

- Multi-axis machine options

- Industry certifications

- Local service support

Call to Action: Need Help Choosing the Right CNC Machine?

Looking to source from the best CNC machine manufacturers in Melbourne?

Contact a local expert Madby tes today streamline your production efficiency.

FAQs:

Q1. What is the most common CNC machine type?

CNC milling machines are the most widely used due to their versatility in producing complex parts.

Q2. What industries use CNC lathes?

CNC lathes are common in automotive, aerospace, and manufacturing industries.

Q3. Is CNC plasma cutting suitable for all materials?

No, it’s ideal for conductive metals like steel and aluminum.

Q4. What’s the difference between EDM and laser cutting?

EDM uses electric sparks for harder metals, while lasers use light for softer, delicate materials.

Q5. How do I find the best CNC machine manufacturers in Melbourne?

Look for providers with good reviews, service guarantees, and a range of machines.

Conclusion:

Understanding the 5 types of CNC machines helps in making informed decisions in production planning and equipment investment.

Always rely on experienced CNC machine manufacturers to ensure your machining needs are met efficiently and reliably.