Choosing the right manufacturing method is crucial for Melbourne businesses that prioritize precision and efficiency. Two popular options are CNC Machining and Laser Cutting, each offering distinct advantages. Whether you’re in the automotive, aerospace, construction, or creative industry, understanding these technologies can help you make informed decisions.

In this guide, we’ll explore the key differences between CNC Machining and Laser Cutting, their applications, and why MadBytes stands out as the leading CNC machine provider in Melbourne.

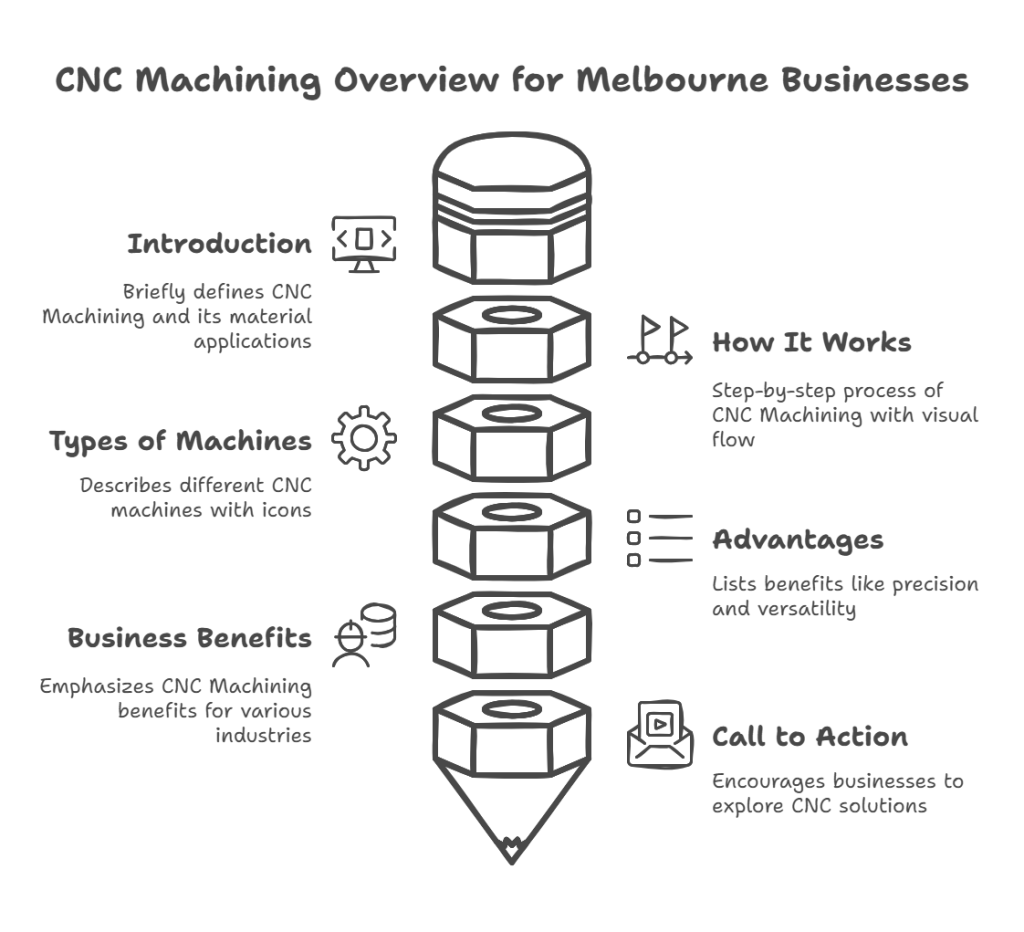

2. Understanding CNC Machining

CNC Machining (Computer Numerical Control) uses automated tools to remove material from a workpiece, creating precise components. It is ideal for businesses requiring high accuracy and durability in metal, plastic, or composite materials.

How CNC Machining Works

- A digital design is converted into machine instructions (G-code).

- The CNC machine follows these instructions to cut, drill, or mill the material.

- Produces complex parts with exceptional accuracy.

Types of CNC Machines

- CNC Mills: Suitable for detailed milling and drilling.

- CNC Lathes: Ideal for cylindrical components.

- CNC Routers: Perfect for wood, plastic, and soft metals.

Advantages of CNC Machining

- High precision and tight tolerances.

- Suitable for mass production.

- Excellent material versatility.

- Efficient for both prototypes and final production.

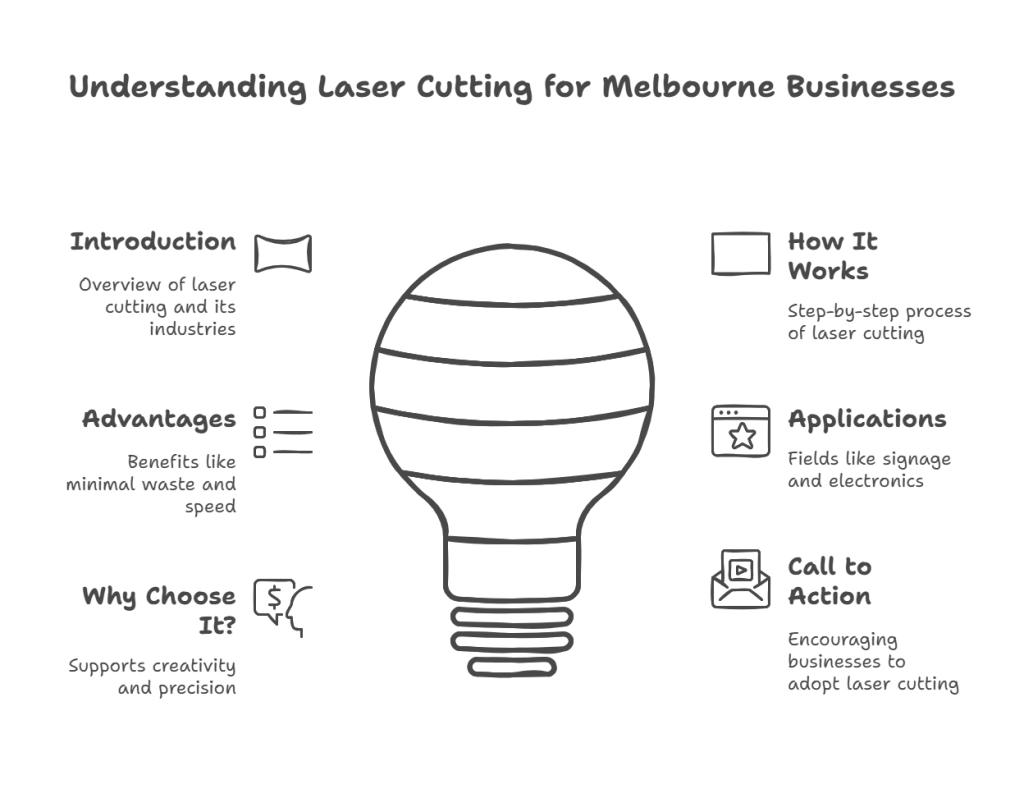

3. Understanding Laser Cutting

Laser Cutting uses a high-powered laser to slice through materials. It is primarily used for intricate designs and thinner materials, making it a preferred choice in industries like signage, electronics, and architectural modeling.

How Laser Cutting Works

- A laser beam melts, burns, or vaporizes the material.

- Computer software controls the path for precise cutting.

- Delivers clean, smooth edges without additional finishing.

Advantages of Laser Cutting

- Ideal for complex and detailed designs.

- Minimal material waste.

- Faster production for thinner materials.

- Suitable for custom, one-off projects.

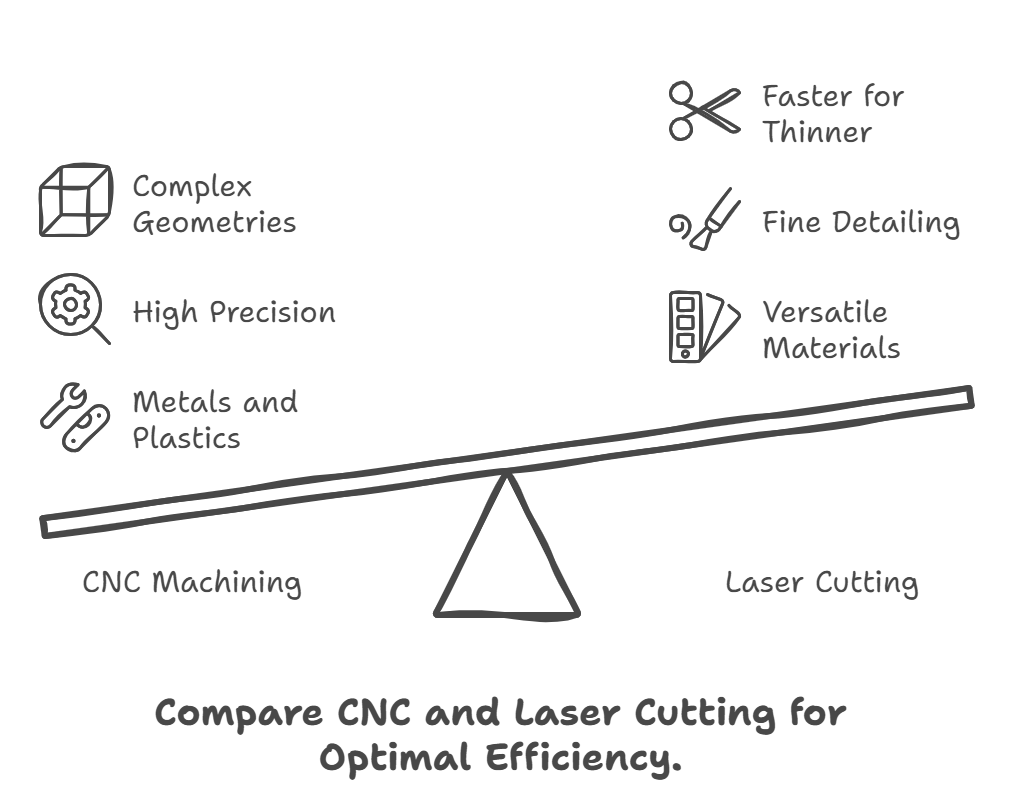

4. Key Differences Between CNC Machining and Laser Cutting

| Factors | CNC Machining | Laser Cutting |

|---|---|---|

| Material Compatibility | Metals, plastics, composites | Thin metals, acrylics, and woods |

| Precision | High accuracy for complex parts | Good for intricate designs |

| Speed | Efficient for bulk production | Faster for thin materials |

| Cost | Cost-effective for large runs | Lower setup cost for prototypes |

| Application | Automotive, aerospace, construction | Signage, electronics, creative arts |

| Environmental Impact | May generate waste | Lower material waste |

5. Which is Best for Your Melbourne Business?

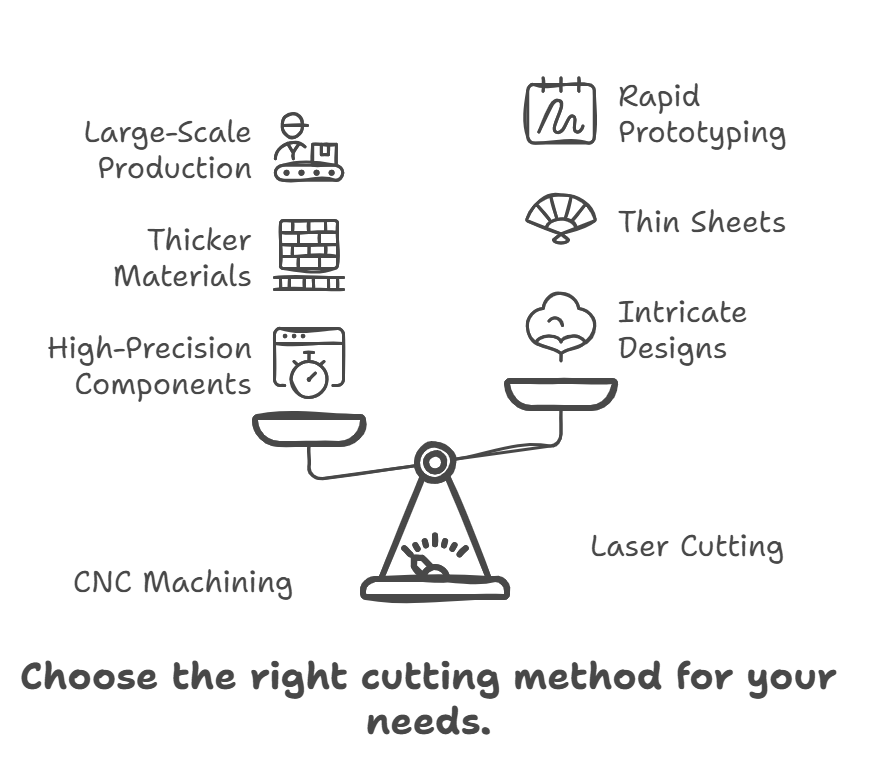

Choose CNC Machining If:

- You need high-precision components for machinery.

- You work with thicker or denser materials.

- Large-scale production is required.

- Structural durability is a priority.

Choose Laser Cutting If:

- You require detailed, intricate designs.

- You are working with thin sheets of metal or plastic.

- Rapid prototyping is necessary.

- Visual appeal is more important than structural strength.

6. Why MadBytes is the Best CNC Machining Service Provider in Melbourne

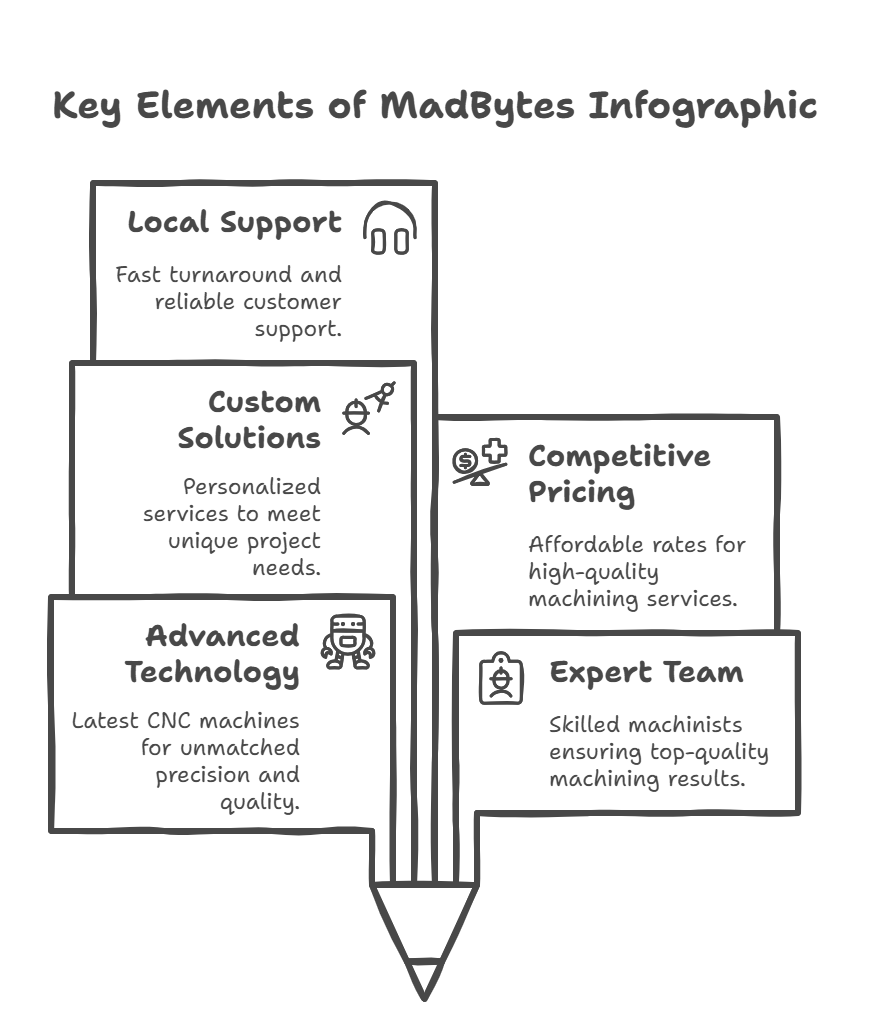

At MadBytes, we offer comprehensive CNC Machining services designed to meet the demands of Melbourne’s industrial sector. Our state-of-the-art machinery, skilled technicians, and commitment to quality make us the preferred choice.

Why Choose Us?

- Advanced Technology: Equipped with the latest CNC machines for unmatched precision.

- Expert Team: Experienced machinists ensure the highest standards.

- Custom Solutions: Tailored machining to meet your specific project needs.

- Competitive Pricing: Affordable rates without compromising quality.

- Local Support: Fast turnaround times and reliable customer service.

Whether you’re in automotive manufacturing, metal fabrication, or custom part production, MadBytes is your trusted CNC partner.

Contact us today to learn how we can bring your designs to life with precision CNC Machining.

7. Conclusion

Both CNC Machining and Laser Cutting offer valuable benefits depending on your project requirements. While Laser Cutting excels in intricate designs and fast prototyping, CNC Machining is the superior choice for robust, high-precision parts.

If you’re seeking a reliable partner for CNC Machining in Melbourne, MadBytes provides exceptional quality, quick delivery, and cost-effective solutions. Reach out to our team to discuss your next project.

8. FAQs

1. Which is more cost-effective: CNC Machining or Laser Cutting?

CNC Machining is generally more cost-effective for larger production runs, while Laser Cutting is ideal for small, intricate projects.

2. Can CNC Machining handle custom designs?

Yes, CNC Machining is highly flexible and can create complex custom parts based on your design files.

3. Is Laser Cutting suitable for thick materials?

Laser Cutting is primarily used for thin materials, while CNC Machining is better suited for thicker materials.

4. What industries benefit most from CNC Machining?

Industries such as automotive, aerospace, and construction heavily rely on CNC Machining for durable and precise parts.

5. How long does a CNC Machining project typically take?

Lead times vary depending on the complexity and volume of the project, but MadBytes offers efficient and timely delivery.

Get a quote from MadBytes and experience top-notch CNC Machining services in Melbourne.